Hyde Aero Products has ambitions to raise all its divisions to SC21 Silver status. With everyone on at least Bronze, it looks like there’s no stopping them.

As associate project director Anthony Williams sees it, the effort it takes more than pays for itself. “No matter which of our companies a customer goes to, they know what we will deliver.”

Hyde Aero Products provides engineering services, specialising in design and manufacture solutions. Within its divisions, the group offers everything from discrete work packages to full turnkey solutions across multiple commodities, working with OEMs and Tier 1 suppliers in aerospace and other highly regulated industries.

The company started in 1968 in a small mill in Hyde, a village in the Greater Manchester area, manufacturing press tools for products such as gas fires. It expanded into aerospace in the 1970s and has worked on countless major high specification, engineering programmes since.

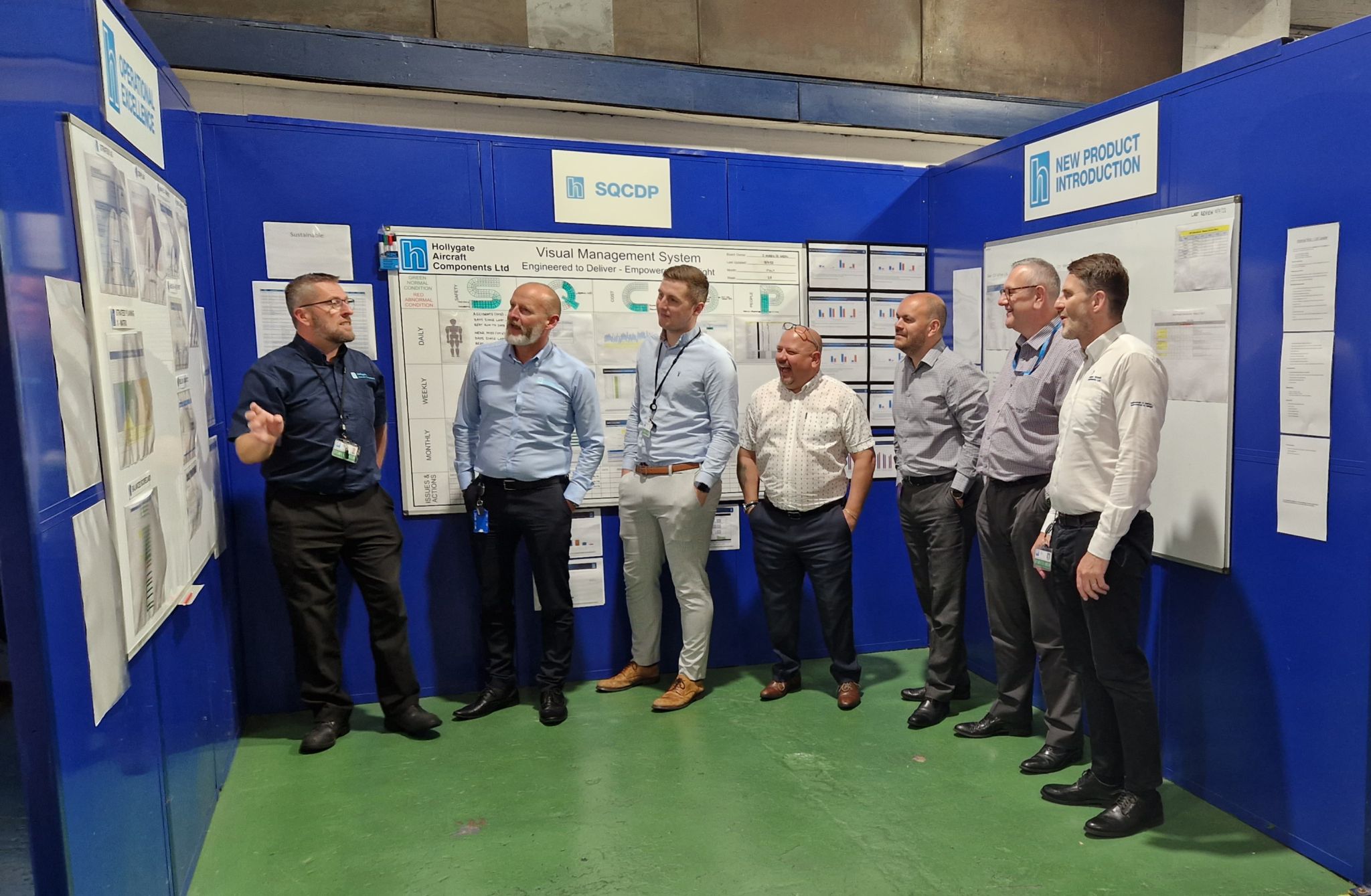

Group company Hollygate Aircraft Components (HAC) launched Hyde on its SC21 journey. Its assessment, in December 2019, was swiftly followed by the company’s first Bronze, awarded in January 2020. HAC now has Silver, as does sister company Hyde Details – Profiles and Forming.

Through their experience, said Williams, “we saw what [SC21] was asking us for, what the criteria was, what we should be doing.” The other group companies had a map to follow, and by 2022 – a year behind schedule due to Covid-19 – all had achieved Bronze.

Last year, every business unit maintained its accreditation. “That doesn’t seem like a big thing, but it is,” he said. Maintaining a 98% delivery record can be a challenge. “If you were to have 2-3 months of bad deliveries for whatever reason, it could scupper you for a good couple of years.”

All Hyde business units signed up to the Supply Chain Solutions (SCS) framework, which supports SC21, in 2023 and expect to have had their assessments by mid-2024. Their sponsor is the OEM Leonardo..

“Where we’ve changed is in our mindset,” said Williams. Feedback from the group’s eight assessments will be used to generate next year’s continuous improvement (CI) roadmaps to achieve their targets.

“Each site had its own individual roadmap,” he said, “and essentially they were all saying the same thing. So instead of reinventing the wheel each time, we’re now looking for where our biggest common challenges and opportunities lie.

“Our main customer base is the OEMs and primes who all support SCS – what better way to appear to them than as a Silver brand.

“How good would that be, to have all the companies in one small cluster all Silver – it would market itself! That’s the plan.”

But SC21 doesn’t stop at Silver, and neither is Hyde. While those group members on Bronze work to upgrade to Silver, the two Silver holders have their own challenge. Said Williams: “We’re pushing them to achieve Gold by 2025, to keep the momentum going forward.”

But SC21 doesn’t stop at Silver, and neither is Hyde. While those group members on Bronze work to upgrade to Silver, the two Silver holders have their own challenge. Said Williams: “We’re pushing them to achieve Gold by 2025, to keep the momentum going forward.”

The main commitment demanded by the SC21 programme is time. “Everyone puts in the time,” he says. “You can see that in the assessment. We all improved on our previous scores. People can see the benefits – that’s the real reward.”

Williams made way for a new CI manager when he moved to his current role last December. A systems improvement engineer was added in 2023 to look at data for insights that will help achieve those Silver and Gold awards. The company also now has a supply chain associate. “It may not sound important to this programme,” says Williams, “but it’s massive in maintaining performance.”

Just how influential is the SC21 programme to Hyde’s business?

“We have a strong and increasing order book,” says Williams, “and while we can’t attribute it all to SC21, we firmly believe it has made a difference.”